LSJ High Pressure Submarines

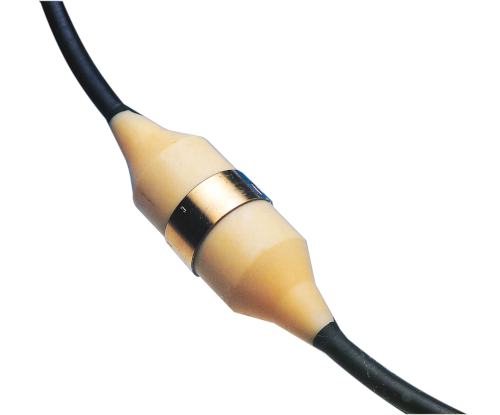

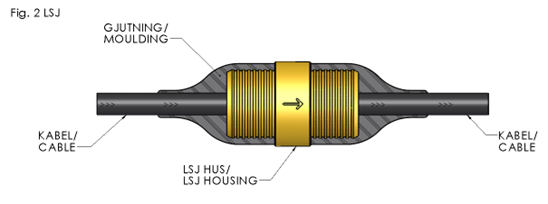

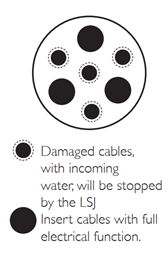

Longitudinal Sealing Cable Joint is used to run an electrical cable through a tank/pipe between two pressure-tight sections and to form a pressure-tight unit with the tank/pipe (RGPH seal) against incoming overpressure media through the cable if it has been damaged or cut in the pressure-tight sections.

The test pressure is 90 bar.

- Custom designed

- Pressure tested up to 90 bar

- Tested and inspected acc. to specification

- EMP-version available

The LSJ longitudinal cable joint is used as protection against incoming overpressure media/water through the pressure hull, vessels or barriers via the cables which have been damaged or cut. Application dimensions and cable types for the LSJ are decided by the customer. Generally the LSJ provides the same requirements as the cable. LSJ penetration are currently used in both submarines and oil platforms. Metal parts can be supplied in different materials according to customers requirement.

PHP and LSJ are in several versions:

LVT = Longitudinal sealed (head-perform).

LVTT = Longitudinal and cross sealed.

E-LVT/E-LVTT = EMP shielded (EMC).

LVT-K = With connector on LP-side (only PHP).

PHP and LSJ are also available with EMC (Electromagnetic Compatibility) which provides the same protection as the above LVT and LVTT but also has built-in protection against EMP (Electromagnetic Pulse) and EMI (Electromagnetic Interference).

This protection is obtained by providing the outer shield on the cable's high-pressure side and low-pressure side with metallic contact with the PHP’s or LSJ's metal housing, which then must have metallic contact with the hull or bulkhead. In some cases, it may be sufficient to connect the shield to only the High Pressure or Low Pressure side.

The PHP and LSJ size, application dimensions and cable types for the PHP or LSJ are decided by the customer.

|

Typical technical data (acc. to customer demands) Hydrostatic pressure: Test pressure: 9 MPa (90bar) or acc. to specification. |

Following testing and inspections are available upon request

• Dimension and visual inspection

• Radiographic examination of moulding

• Leak detection test

• Hydrostatic pressure test

• High voltage test

• Insulation resistance test

• Conductor continuity and function test

• Result verification and inspection report/certificate

• Or other tests specified by the customer