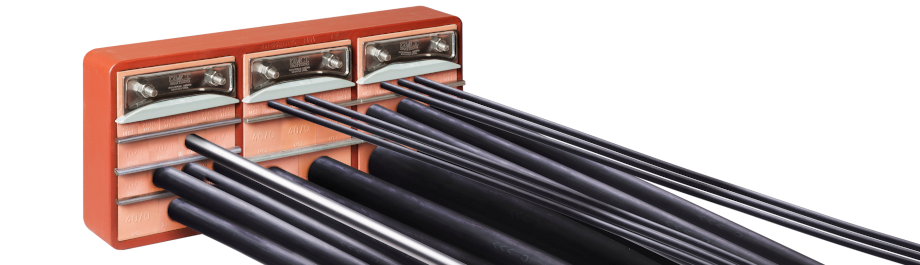

E-RGS

E-RGS cable and pipe transit are welded in high-risk maritime and offshore environments to minimize danger by preventing the spread of fire, water, gas, chemicals, EMI and other hazards substances.

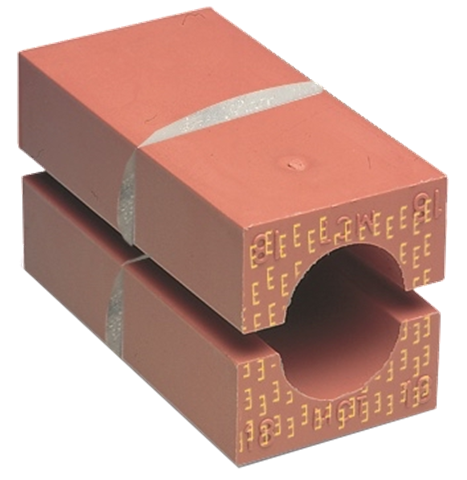

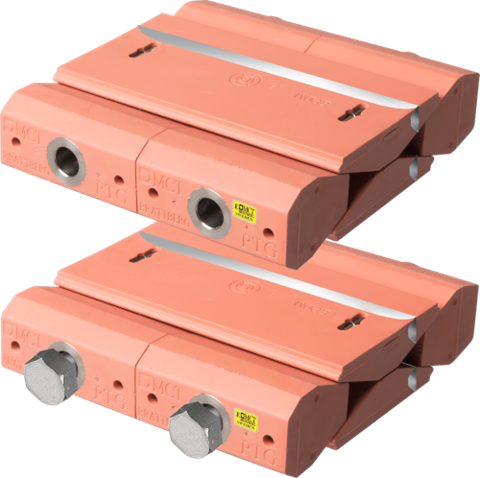

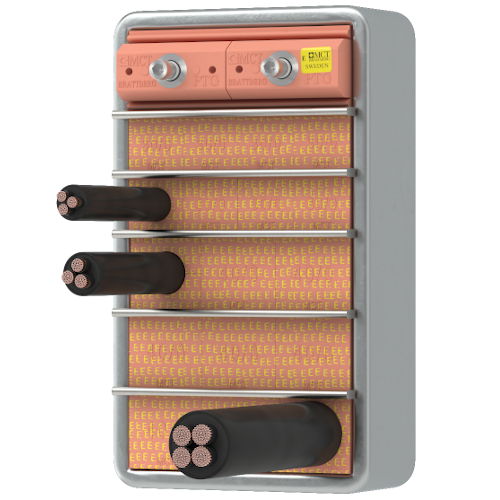

The system consists of a frame, rubber blocks and a compression unit.

The frame is welded to a marine structure and packed with rubber blocks suited for each cable and pipe dimension. The compression unit is inserted to compress the rubber blocks against cables and pipes to establish a tight seal.

Benefits of MCT Brattberg E-series system

- Protects against electrical and magnetic interference (EMI), “bugging”, electronic sabotage (SEMP) and static electricity (ESD).

- Assists cable management.

- Integral earthing between cables and wall screen.

- Also seals the penetration against the passage of fire, water, gas, sound and environmental hazards.

- E-Series approved for Grounding and Bounding

- System can be dismantled and re-used.

Overview

E-RGS has a standard internal width of 120 mm (4.72”) and is 60 mm (2.36”) deep.

Standard frames come in eight sizes: 1, 2, 3, 4, 5, 6, 7, and 8.

The internal width can be 60.5 ± 1 (Size 1,3,5,7) or 120.5 ± 1 (2,4,6,8).

Note that there can be limitations in type-approvals & certificates, making certain sizes inapplicable.

They may be used in both vertical and/or horizontal multiple frames. The E-RGS is welded into an accurately pre-cut hole in the deck or bulkhead. As with all our frames, E-RGS is produced in steel, stainless steel, or aluminium.

For installations where cables are already in place, specify E-RGSO, which has a removable end.

The EMC secret is a tempered metal sheet which systematically stops electrical current from passing along the cable screening through the seal and successfully function as an extended wall screen.

For further technical information see tables in our Online Catalogue:

Performance

Maritime resistance to fire:

Class A0, A60, H0, H60, H120 - IMO FTP Code 2010

(For more info see Certificates)

Water-tightness:

6 Bar water pressure load for 60 minutes - DNVGL-CP-0165

Gas-tightness:

4 Bar air pressure load for 30 minutes - DNVGL-CP-0165

Enclosure degree of protection Nema 250:

3R; 4X; 12 - Nema 250-1st

Enclosure degree of protection IP:

IP65; IP66; IP67; IP68 2 meters 60 min - IEC 60529

Resistance to jet fire:

RGSbtb- J120 & JF

RGS - J60 & JF

(Contact MCT Brattberg for application details)

Data

Trade name:

MCT Brattberg E-RGS multi cable/pipe transit system

Variations:

See TECH SPECS

Working temperature:

-65 to +70 degrees C

Lycron data

Read Lycron data sheet:

Data sheet Lycron

Lycron is halogen free and flame retardant.![]()

For all approvals, please also see Certificates

Instructions

EMC

- All dimensions are exactly the same for the standard MCT Brattberg components.

- All Insert Blocks are marked with yellow marking (see instructions).

Grounding and Bonding

- For grounding & bonding applications standard presswedge or endpacking is sufficient.

- Series RGS, RGB, RGG, and E-RGP These products are primarily intended for grounding and bonding of communication, instrument, power, braid or wire armored cables and copper pipes, up to max. 1 AWG.

- Plugs and Wraps are only for use in Grounding and Bonding applications, not EMC.

Correct and safe installations

To achieve the highest standard of safety, a cable or pipe transit must be installed correctly. As there are many different types of frame – which may be either welded, bolted or glued into position – and insert block, it is essential that installers known when to use the most appropriate installation method.

For more information, please view following instructions, videos or download manuals as PDFs.

Download pdf instructions

For more information visit Documents & instructions

Multiple frames

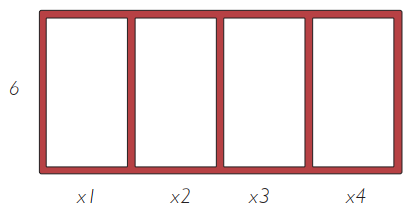

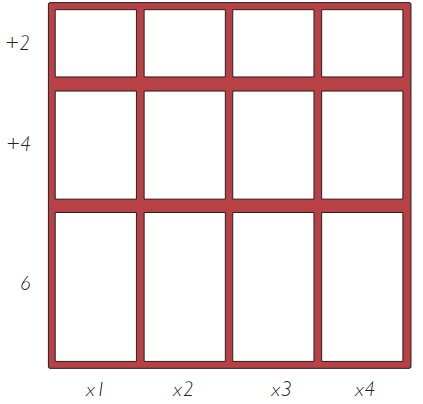

HORIZONTAL MULTIPLE FRAMES

Horizontal multiple frames are described by listing the frame type and size x the desired number of horizontal openings.

Designation (starting at bottom):

Frame type 6x4

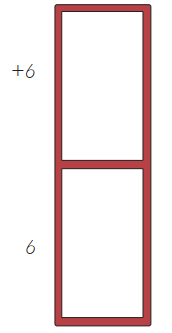

VERTICAL MULTIPLE FRAMES

Vertical multiple frames are described by listing the bottom frame type and size + the next frame type and size.

Designation (starting at bottom):

(frame type) 6+6+4 and (frame type) 6+4+2

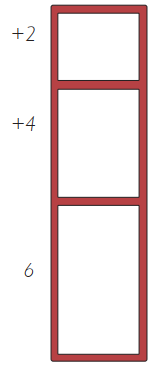

VERTICAL AND HORIZONTAL MULTIPLE FRAMES

List the entire vertical frames x the desired number of horizontal repetitions.

Designation (starting at bottom):

(frame type) 6+4+2x4

NOTE: All multiple frame designations must be preceded by the frame type.