MCT Ex - Round transit At Sea On land Ex EMC

These Ex cable and pipe transits are used in high-risk maritime, offshore and land-based environments to minimize danger by preventing the spread of fire, water, gas, chemicals and other hazards substances.

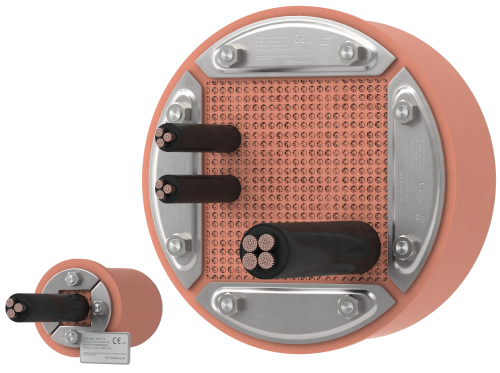

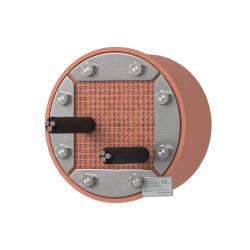

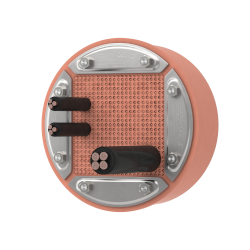

The system consists of a round rubber frame (RGP Ex) and rubber blocks. The RGP Ex system must be installed with a MCT Brattberg sleeve as a kit, and packed with rubber blocks suited for each cable and pipe dimension. The compression bolts are tightened to compress the rubber blocks against cables and pipes to establish a tight seal.

Benefits of MCT Brattberg Ex systems

- Ex rated transit for hazardous environments

- Assists cable management

- Seals the penetration against the passage of fire, water, gas, sound and environmental hazards

- Can be combined with special EMC modules and for Grounding and Bounding

- Unlike other brands our system can be dismantled and re-used

- Cable dimension marked on block

- No adaptation of standard blocks needed

Overview

The marking of the equipment and protective system

Group II Category 2GD Ex eb IIC Gb Ex tb IIIC Db Tamb (-40°C to+70°C)

- MCT Brattberg RGP Ex system must be installed with supplied sleeve.

RGP Ex

Circular Ex rated multi cable & pipe transits for assembly only in sleeves.

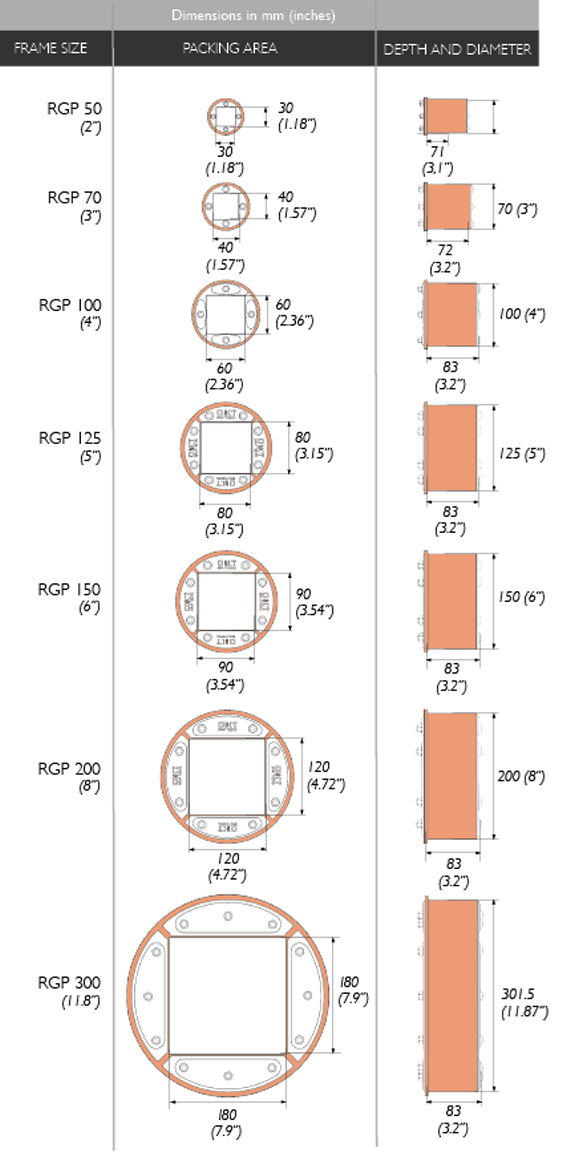

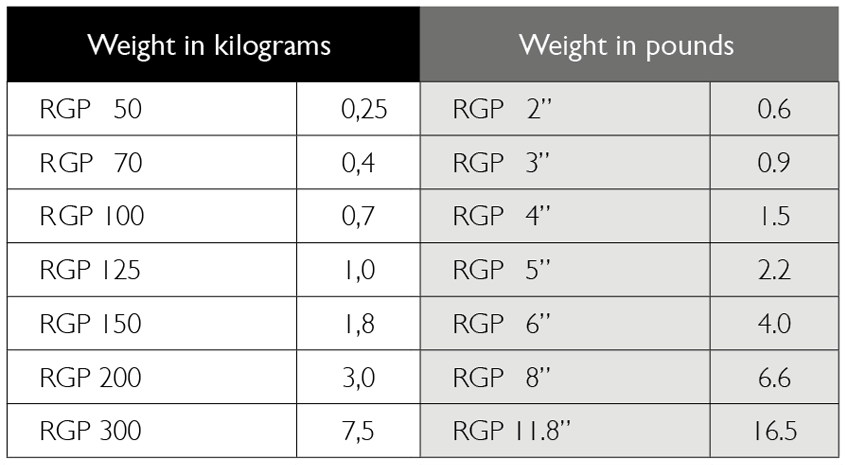

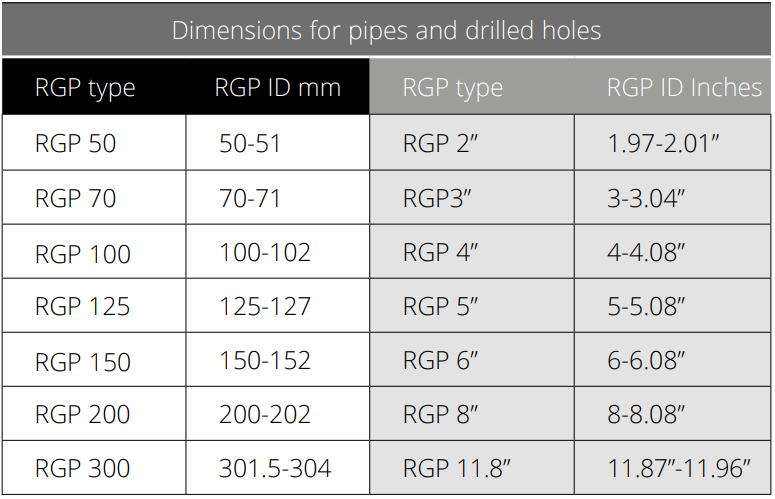

It is available diameters 50, 70, 100, 125, 150, 200 mm, 3", 4", 5", 6", 8" and is packed with MCT Ex Insert blocks. The hardware is available in galvanized or stainless steel (316L).

Approved RGP's listed below

RGP Ex 50 (2")

RGP Ex 70 (2.75") or RGP Ex 3" (76.2mm)

RGP Ex 100 (3.93") or RGP Ex 4" (101.6mm)

RGP Ex 125 (4.92") or RGP Ex 5" (127mm)

RGP Ex 150 (5.90") or RGP Ex 6" (152.4mm)

RGP Ex 200 (7.87") or RGP Ex 8" (203.2mm)

RGP has an open side intended for installation in holes where cables have already been pulled.

Sleeves are available in several diameters to suit each RGP size. They can be welded, casted or bolted to a structure. The standard materials are mild steel, stainless steel or aluminum.

Technical Specifications

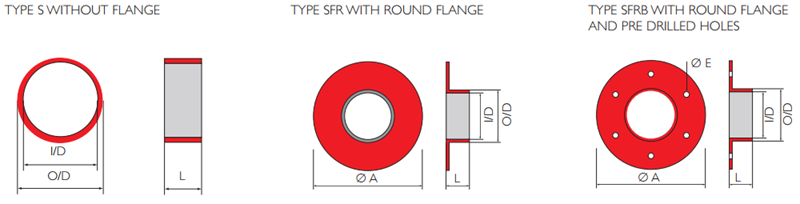

Sleeves

MCT Brattberg standard sleeves are available in seven sizes, for welding or bolting to the structure. The standard materials are mild steel, stainless steel and aluminium. SFRB is also available in an open version (SFRBO).

MCT Brattberg standard sleeves are available in seven sizes, for welding or bolting to the structure. The standard materials are mild steel, stainless steel and aluminium. SFRB is also available in an open version (SFRBO).

- SFR/SFRB are supplied as kits, complete with drilled holes, bolts, nuts, washers and a gasket or sealing compound.

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 50 | S | Primer | 2-00350550 | 0,6 | 1.3 |

| RGP 50 | SFR | Primer | 2-00350570 | 1,2 | 2.6 |

| RGP 50 | SFRB | Primer | 2-00350590 | 1,2 | 2.6 |

| RGP 50 | SFRBO | Primer | 2-00360590 | 1,2 | 2.6 |

| RGP 50 | S | Galvanized | 2-00350551 | 0,6 | 1.3 |

| RGP 50 | SFR | Galvanized | 2-00350571 | 1,2 | 2.6 |

| RGP 50 | SFRB | Galvanized | 2-00350591 | 1,2 | 2.6 |

| RGP 50 | SFRBO | Galvanized | 2-00360591 | 1,2 | 2.6 |

| RGP 50 | S | Stainless steel | 2-00350552 | 0,6 | 1.3 |

| RGP 50 | SFR | Stainless steel | 2-00350572 | 1,2 | 2.6 |

| RGP 50 | SFRB | Stainless steel | 2-00350592 | 1,2 | 2.6 |

| RGP 50 | SFRBO | Stainless steel | 2-00360592 | 1,2 | 2.6 |

| RGP 50 | S | Aluminium | |||

| RGP 50 | SFR | Aluminium | |||

| RGP 50 | SFRB | Aluminium | |||

| RGP 50 | SFRBO | Aluminium | |||

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 70 | S | Primer | 2-00350700 | 0,8 | 1.8 |

| RGP 70 | SFR | Primer | 2-00350720 | 2,1 | 4.6 |

| RGP 70 | SFRB | Primer | 2-00350740 | 2,1 | 4.6 |

| RGP 70 | SFRBO | Primer | 2-00360740 | 2,1 | 4.6 |

| RGP 70 | S | Galvanized | 2-00350701 | 0,8 | 1.8 |

| RGP 70 | SFR | Galvanized | 2-00350721 | 2,1 | 4.6 |

| RGP 70 | SFRB | Galvanized | 2-00350741 | 2,1 | 4.6 |

| RGP 70 | SFRBO | Galvanized | 2-00360741 | 2,1 | 4.6 |

| RGP 70 | S | Stainless steel | 2-00350702 | 0,8 | 1.8 |

| RGP 70 | SFR | Stainless steel | 2-00350722 | 2,1 | 4.6 |

| RGP 70 | SFRB | Stainless steel | 2-00350742 | 2,1 | 4.6 |

| RGP 70 | SFRBO | Stainless steel | 2-00360742 | 2,1 | 4.6 |

| RGP 70 | S | Aluminium | |||

| RGP 70 | SFR | Aluminium | |||

| RGP 70 | SFRB | Aluminium | |||

| RGP 70 | SFRBO | Aluminium | |||

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 100 | S | Primer | 2-00351000 | 1,3 | 2.8 |

| RGP 100 | SFR | Primer | 2-00351020 | 2,9 | 6.4 |

| RGP 100 | SFRB | Primer | 2-00351040 | 2,9 | 6.4 |

| RGP 100 | SFRBO | Primer | 2-00361040 | 2,9 | 6.4 |

| RGP 100 | S | Galvanized | 2-00351001 | 1,3 | 2.8 |

| RGP 100 | SFR | Galvanized | 2-00351021 | 2,9 | 6.4 |

| RGP 100 | SFRB | Galvanized | 2-00351041 | 2,9 | 6.4 |

| RGP 100 | SFRBO | Galvanized | 2-00361041 | 2,9 | 6.4 |

| RGP 100 | S | Stainless steel | 2-00351002 | 1,3 | 2.8 |

| RGP 100 | SFR | Stainless steel | 2-00351022 | 2,9 | 6.4 |

| RGP 100 | SFRB | Stainless steel | 2-00351042 | 2,9 | 6.4 |

| RGP 100 | SFRBO | Stainless steel | 2-00361042 | 2,9 | 6.4 |

| RGP 100 | S | Aluminium | |||

| RGP 100 | SFR | Aluminium | |||

| RGP 100 | SFRB | Aluminium | |||

| RGP 100 | SFRBO | Aluminium | |||

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 125 | S | Primer | 2-00351200 | 1,6 | 3.5 |

| RGP 125 | SFR | Primer | 2-00351220 | 3,7 | 8.2 |

| RGP 125 | SFRB | Primer | 2-00351240 | 3,7 | 8.2 |

| RGP 125 | SFRBO | Primer | 2-00361240 | 3,7 | 8.2 |

| RGP 125 | S | Galvanized | 2-00351201 | 1,6 | 3.5 |

| RGP 125 | SFR | Galvanized | 2-00351221 | 3,7 | 8.2 |

| RGP 125 | SFRB | Galvanized | 2-00351241 | 3,7 | 8.2 |

| RGP 125 | SFRBO | Galvanized | 2-00361241 | 3,7 | 8.2 |

| RGP 125 | S | Stainless steel | 2-00351202 | 1,6 | 3.5 |

| RGP 125 | SFR | Stainless steel | 2-00351222 | 3,7 | 8.2 |

| RGP 125 | SFRB | Stainless steel | 2-00351242 | 3,7 | 8.2 |

| RGP 125 | SFRBO | Stainless steel | 2-00361242 | 3,7 | 8.2 |

| RGP 125 | S | Aluminium | |||

| RGP 125 | SFR | Aluminium | |||

| RGP 125 | SFRB | Aluminium | |||

| RGP 125 | SFRBO | Aluminium | |||

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 150 | S | Primer | 2-00351500 | 1,9 | 4.2 |

| RGP 150 | SFR | Primer | 2-00351520 | 4,2 | 9.3 |

| RGP 150 | SFRB | Primer | 2-00351540 | 4,2 | 9.3 |

| RGP 150 | SFRBO | Primer | 2-00361540 | 4,2 | 9.3 |

| RGP 150 | S | Galvanized | 2-00351501 | 1,9 | 4.2 |

| RGP 150 | SFR | Galvanized | 2-00351521 | 4,2 | 9.3 |

| RGP 150 | SFRB | Galvanized | 2-00351541 | 4,2 | 9.3 |

| RGP 150 | SFRBO | Galvanized | 2-00361541 | 4,2 | 9.3 |

| RGP 150 | S | Stainless steel | 2-00351502 | 1,9 | 4.2 |

| RGP 150 | SFR | Stainless steel | 2-00351522 | 4,2 | 9.3 |

| RGP 150 | SFRB | Stainless steel | 2-00351542 | 4,2 | 9.3 |

| RGP 150 | SFRBO | Stainless steel | 2-00361542 | 4,2 | 9.3 |

| RGP 150 | S | Aluminium | |||

| RGP 150 | SFR | Aluminium | |||

| RGP 150 | SFRB | Aluminium | |||

| RGP 150 | SFRBO | Aluminium | |||

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 200 | S | Primer | 2-00352000 | 2,6 | 5.7 |

| RGP 200 | SFR | Primer | 2-00352020 | 5,1 | 11.2 |

| RGP 200 | SFRB | Primer | 2-00352040 | 5,1 | 11.2 |

| RGP 200 | SFRBO | Primer | 2-00362040 | 5,1 | 11.2 |

| RGP 200 | S | Galvanized | 2-00352001 | 2,6 | 5.7 |

| RGP 200 | SFR | Galvanized | 2-00352021 | 5,1 | 11.2 |

| RGP 200 | SFRB | Galvanized | 2-00352041 | 5,1 | 11.2 |

| RGP 200 | SFRBO | Galvanized | 2-00362041 | 5,1 | 11.2 |

| RGP 200 | S | Stainless steel | 2-00352002 | 2,6 | 5.7 |

| RGP 200 | SFR | Stainless steel | 2-00352022 | 5,1 | 11.2 |

| RGP 200 | SFRB | Stainless steel | 2-00352042 | 5,1 | 11.2 |

| RGP 200 | SFRBO | Stainless steel | 2-00362042 | 5,1 | 11.2 |

| RGP 200 | S | Aluminium | |||

| RGP 200 | SFR | Aluminium | |||

| RGP 200 | SFRB | Aluminium | |||

| RGP 200 | SFRBO | Aluminium | |||

| Designation | Sleeve Type | Material | Artnr | Weight kilograms | Weight pounds |

| RGP 300 | S | Primer | 2-00353000 | 4,5 | 9.9 |

| RGP 300 | SFR | Primer | 2-00353020 | 8,5 | 18.7 |

| RGP 300 | SFRB | Primer | 2-00353040 | 8,5 | 18.7 |

| RGP 300 | SFRBO | Primer | 2-00363040 | 8,5 | 18.7 |

| RGP 300 | S | Galvanized | 2-00353001 | 4,5 | 9.9 |

| RGP 300 | SFR | Galvanized | 2-00353021 | 8,5 | 18.7 |

| RGP 300 | SFRB | Galvanized | 2-00353040 | 8,5 | 18.7 |

| RGP 300 | SFRBO | Galvanized | 2-00363041 | 8,5 | 18.7 |

| RGP 300 | S | Stainless steel | 2-00353002 | 4,5 | 9.9 |

| RGP 300 | SFR | Stainless steel | 2-00353022 | 8,5 | 18.7 |

| RGP 300 | SFRB | Stainless steel | 2-00353042 | 8,5 | 18.7 |

| RGP 300 | SFRBO | Stainless steel | 2-00363042 | 8,5 | 18.7 |

| RGP 300 | S | Aluminium | |||

| RGP 300 | SFR | Aluminium | |||

| RGP 300 | SFRB | Aluminium | |||

| RGP 300 | SFRBO | Aluminium |

Performance

Resistance to fire:

EI 30-60-120-180 & E 30-60-120-240

(Contact MCT Brattberg for application details)

Declaration of Performance can be found here: CE

Maritime resistance to fire:

Class A0, A60, H0, H60, H120 - IMO FTP Code 2010

Water-tightness:

5 Bar water pressure load for 60 minutes - DNVGL-CP-0165

- RGP-300: 3 Bar water pressure load for 60 minutes

Gas-tightness:

3 Bar air pressure load for 30 minutes - DNVGL-CP-0165

- RGP-300: 2 Bar air pressure load for 30 minutes

Enclosure degree of protection Nema 250:

3R; 4X; 12 - Nema 250-1st

Enclosure degree of protection IP:

IP65; IP66; IP67; IP68 2 meters 60 min - IEC 60529

Data

Trade name:

MCT Brattberg RGP Ex multi cable/pipe transit system

Variations:

See Overview

Working temperature:

-40 to +70 degrees C

Lycron data

Read Lycron data sheet:

Data sheet Lycron

Lycron is halogen free and flame retardant.![]()

For all approvals, please also see Certificates

Instructions

Ex

- Available as both equipment and component

Component:

Component is not intended to be used alone and requires additional consideration when incorporated into other equipment or systems for use in explosive atmospheres (refer to IEC 60079-0)

- Ex system combined with EMC has yellow marking on the front face (see EMC instructions)

- MCT Brattberg RGP Ex system must be installed with supplied sleeve.

Correct and safe installations

To achieve the highest standard of safety, a cable or pipe transit must be installed correctly. As there are many different types of frame – which may be either welded, bolted or glued into position – and insert block, it is essential that installers known when to use the most appropriate installation method.

For more information, please view following instructions, videos or download manuals as PDFs.

PRESSURE-TIGHT INSTALLATION

RGP Ex All contact surfaces between the pipe and the RGP plug must be cleaned carefully prior to installation. Do not use any lubricant on these surfaces. All blocks must be lubricated carefully with MCT Brattberg lubricant. The penetration must not be subjected to pressure for at least 48 hours after installation. This is to allow the pressure to equalise throughout the penetration. It will take more time for the pressure to equalise at temperatures below 20°C.

Note: If the installation is subjected to pressure, all components must be replaced after removal and refitting.

Download pdf instructions

Insert Blocks Ex

Ex and ATEX requirements are very strict, some Ex Insert blocks may not be approved with certain systems.

Here you find Insert blocks that are approved with RGP Ex.

Standard Block Ex

Following standard blocks in the table are approved:

Spare Block Ex

Following Spare blocks in the table are approved:

AddBlock Ex

Following Addblocks in the table are approved:

Read more about Insert Blocks in general

Components

Installations

Examples of installations on different sites: